30% Glass Filled PEEK Performance

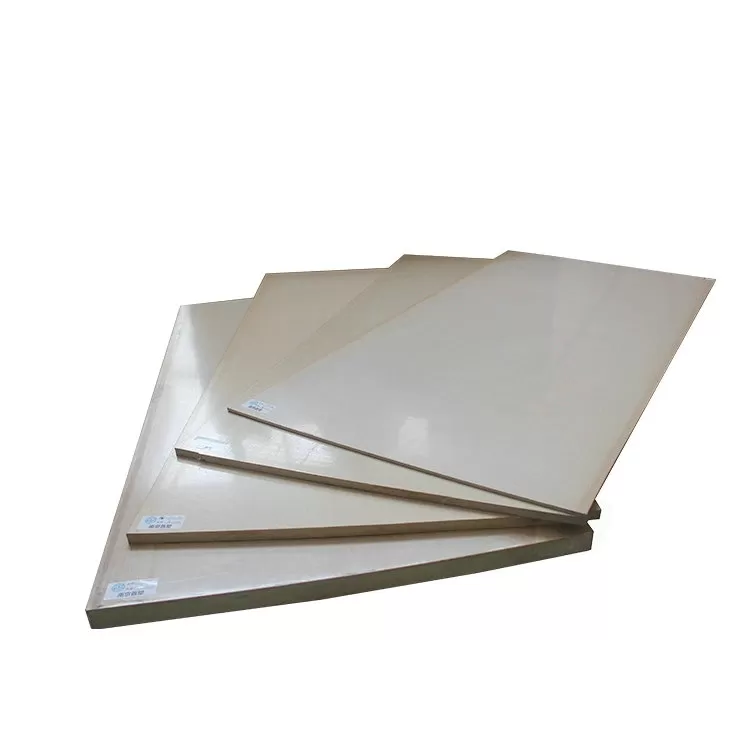

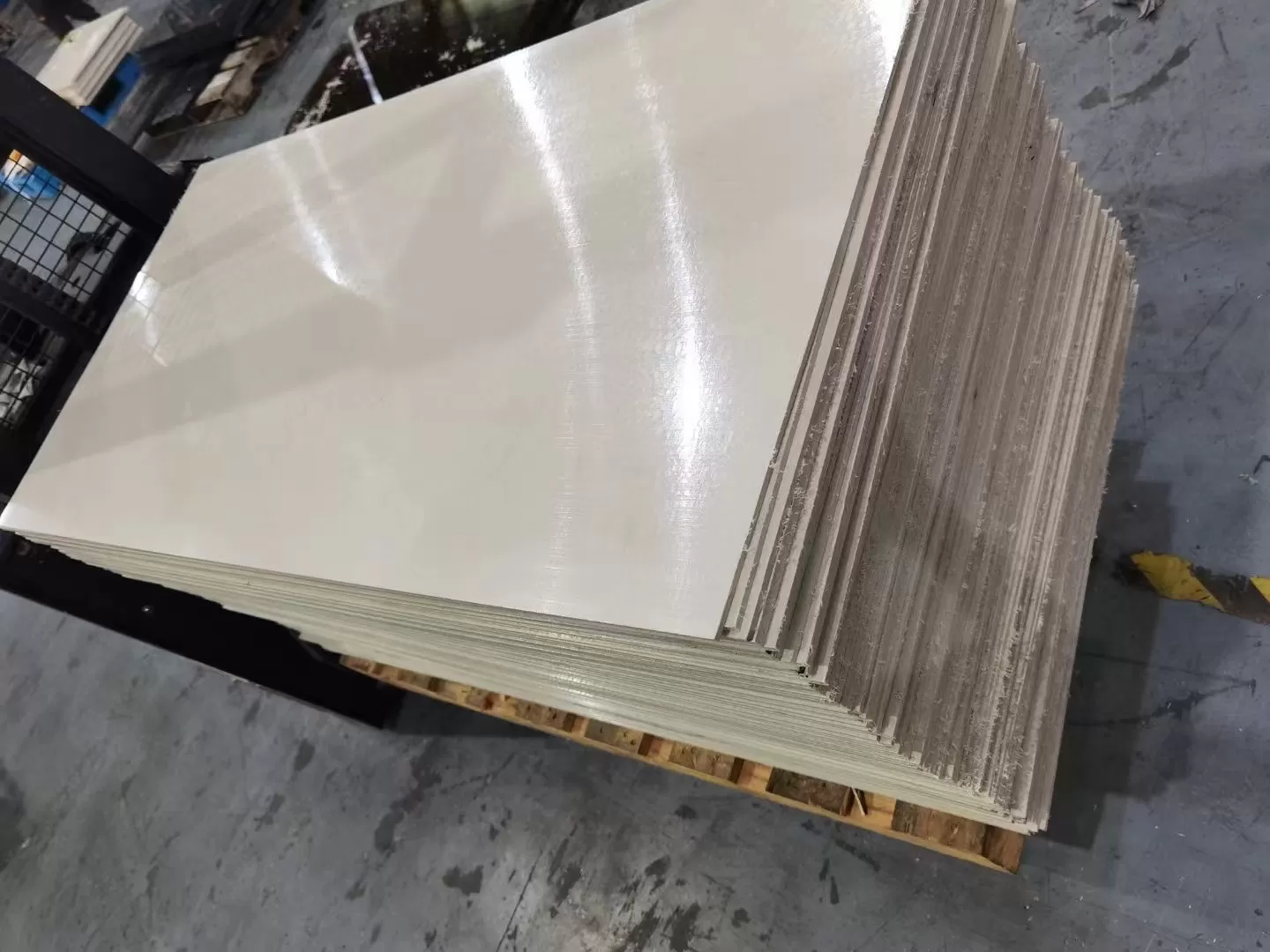

Our PEEK Glass Filled Sheet is engineered with 30% glass reinforcement, delivering enhanced mechanical strength, thermal stability, and chemical resistance. With comprehensive glass filled PEEK material properties, competitive glass filled peek sheet price (40-70 USD/kg), and a range of glass peek sheet sizes, our sheets are the perfect solution for high-performance industrial applications.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Glass Filled Sheet – Advanced 30% Glass Reinforced PEEK for Superior Performance

Our PEEK Glass Filled Sheet is a high-performance engineering material that integrates 30% glass reinforcement to deliver exceptional durability, strength, and resistance under demanding conditions. Designed for applications in aerospace, automotive, industrial, and chemical processing, this sheet offers robust performance and long-term reliability.

Key Technical Features

Enhanced Material Properties: Benefit from outstanding glass filled PEEK material properties that include superior mechanical strength, excellent thermal stability, and enhanced chemical resistance. This makes our sheets ideal for high-stress and high-temperature environments.

Versatile Dimensions: Available in a variety of glass peek sheet sizes, our product can be customized to meet your specific project requirements, ensuring seamless integration into your manufacturing processes.

Competitive Pricing: We offer a transparent and competitive glass filled peek sheet cost, with prices ranging from 40-70 USD/kg. Whether you are comparing a 30 glass peek sheet price or looking for a reliable source for 30 glass peek sheet for sale, our pricing structure provides excellent value for premium quality.

Application-Ready: Perfect for demanding industrial applications, our PEEK Glass Filled Sheet is engineered to solve critical challenges in areas requiring high durability, precision, and consistent performance.

Applications & Benefits:

Aerospace & Automotive: Utilized in lightweight structural components and high-performance parts that require exceptional strength and heat resistance.

Industrial & Chemical Processing: Provides robust performance in corrosive environments where high chemical resistance and dimensional stability are crucial.

Advanced Engineering Projects: Ideal for custom solutions where precise material properties and a range of available sizes are key to success.

Why Choose Our PEEK Glass Filled Sheet?

Trusted Quality: Our sheets are manufactured to the highest standards, ensuring that you receive a product that meets rigorous industrial requirements.

Comprehensive Support: Detailed documentation on glass filled PEEK material properties is available to help you understand the full potential of our product and optimize your design.

Flexible Options: With an extensive range of glass peek sheet sizes and competitive pricing, our product is tailored to fit various technical applications and budgets.

Invest in our PEEK Glass Filled Sheet to enhance the performance and durability of your projects. Contact us today to get a quote, request more technical details, or place your order for a cost-effective, high-quality solution at a competitive glass filled peek sheet price.

_______________________________________________________________________________________________________________________________________________________________________

ARKPEEK Materials Composition

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

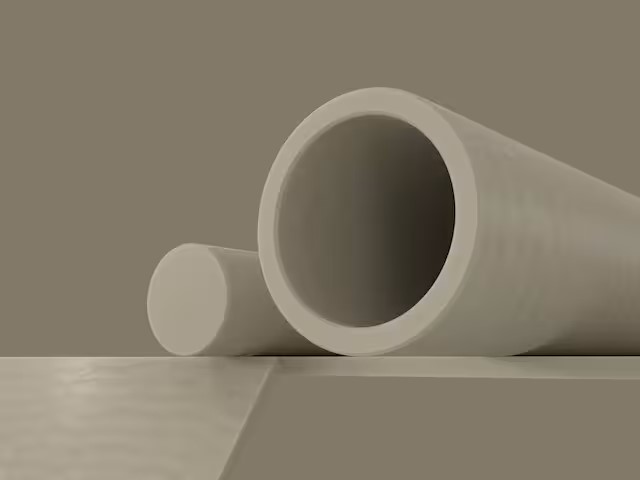

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

_______________________________________________________________________________________________________________________________________________________________________

Glass PEEK Sheet Sizes

| NO. | Dimension (mm) | Weight ( g ) |

| 1 | 0.5*700*1000 | 480 |

| 2 | 1*700*1000 | 950 |

| 3 | 2*700*1000 | 1900 |

| 4 | 3*700*1000 | 2800 |

| 5 | 4*650*1000 | 3400 |

| 6 | 5*650*1000 | 4300 |

| 7 | 67×31×1000 | 2700 |

| 8 | 80x15x1000 | 1560 |

| 9 | 100x25x1000 | 3100 |

| 10 | 120x38x1000 | 5500 |

| 11 | 195×33×1000 | 8365 |

| 12 | 175x162×1000 | 36855 |

| 13 | 395x12.5x1000 | 6419 |

| 14 | 422x15x1000 | 8229 |

| 15 | 422x66x1000 | 36207 |

| 16 | Insulation block (with Utype)280x45x1000 | 15000 |

| 17 | 600×6x1000 | 4680 |

| 18 | 600x8×1000 | 6240 |

| 19 | 600×9×1000 | 7020 |

| 20 | 600x15x1000 | 11700 |

| 21 | 600×20x1000 | 15600 |

| 22 | 600×25×1000 | 19500 |

| 23 | 600x30x1000 | 23400 |

| 24 | 600x35×1000 | 27300 |

| 25 | 600×40×1000 | 31200 |

| 26 | 600x45x1000 | 35100 |

| 27 | 600x50×1000 | 39000 |

| 28 | 600x60x1000 | 46800 |

| 29 | 800x20x1000 | 20800 |

| 30 | 800x30x1000 | 31200 |